Welcome to part 3 of our Fireproofing series. In part 1 of the series, you heard about Brindley Engineering’s approach to post fire evaluations and fire and fireproofing technology. In part 2, you learned about API 2218 and its importance. Today we explore the importance of field evaluations, maintenance programs, repair engineering and design, and QAQC.

Q: Why are field evaluations important for fireproofing?

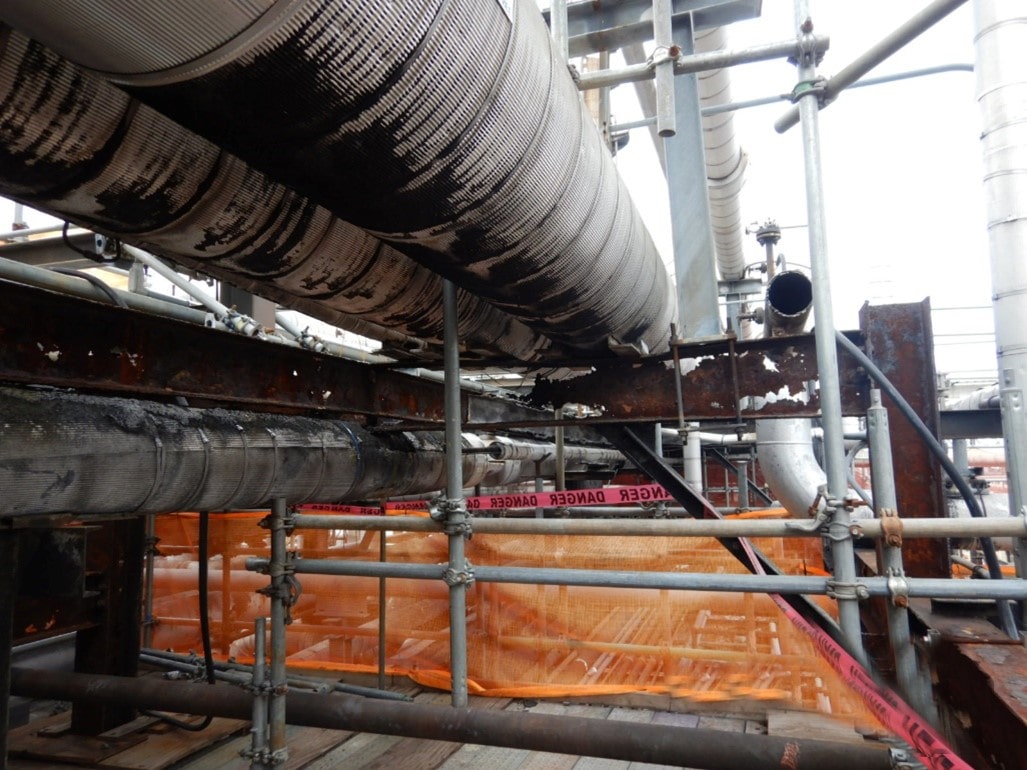

A: Field evaluations are critical to understanding the current and projected condition of structures and fireproofing to provide the greatest safety at the least expense. Brindley Engineering’s inspectors understand the severity of the defects, the likelihood of failure and the potential for damage to the underlying steel. This understanding, combined with our proprietary modeling techniques, provides the Owner the knowledge they need to fully understand and control their risk, allocate budget based on data, and show a proven cost-benefit to maintenance dollars expended.

Q: What advice can you give clients about starting and maintaining a fireproofing maintenance program?

A: Knowing how much and where to spend maintenance budgets is a complex problem but it is a challenge Brindley Engineering has attacked head on and continues to refine with years of data behind it. We have worked with owners throughout the U.S. and beyond to provide peace of mind that their infrastructure is well protected and that their budgets are being put to good use.

Q: What is your process for starting a maintenance program? What are some expected outcomes?

A: We establish or improve maintenance programs by providing organization, work prioritization, planning, scheduling, cost controls, and reporting. Cost efficiency is enhanced by determining key performance indicators (KPIs) and tracking program implementation for continual improvement.

Q: What if repairs are needed? How do you choose the right plan and materials to use?

A: Brindley Engineering has unparalleled databases of materials, failure patterns, root causes, and underlying steel defects that can provide statistical analyses to improve predictability and decrease costs of maintenance programs. We have written fireproofing specifications for multiple facilities, implementing improvements on standard placement procedures and mix designs. In addition to providing inspection and engineering, we also provide on-site construction quality services on repairs to underlying structural steel as well as the application of coatings and fireproofing.

Q: What makes Brindley Engineering qualified to handle repairs and design?

A: With NACE inspectors, CWI’s, Concrete Surface Repair Technicians, and ACI concrete inspectors, Brindley Engineering is uniquely qualified as an engineering firm that can provide additional value with certified technical personnel.

Q: How do I know if investing in a maintenance program is worth it? How do I evaluate its performance?

A: Most facilities have very little, if any, proactive fireproofing maintenance programs. The result is that both the fireproofing and underlying steel deteriorate, creating dangerous conditions and very costly repairs. A proactive system will improve safety and drive down maintenance costs significantly. Despite the benefits, many facilities are reluctant to invest in these programs because they can seem overwhelming, and they lack data regarding the return on their investment. The performance of the program is gauged by the improvement in safety and the cost of the program compared to the savings it derives.

Brindley Engineering provides the planning, systems, technical knowledge, execution, and financial analysis to ensure that the facility is achieving quantifiable value for their investment.

About Brindley Engineering Brindley Engineering was founded with a vision to provide the highest level of service to clients in capital & maintenance projects, reliability initiatives, and construction solutions. We’ve developed a world-class, multidisciplinary team of engineers, technicians, and designers that share that vision.

- Read Part 1 in the series: How Brindley Engineering performs a post fire evaluation

- Read Part 2 in the series: How Brindley Engineering performs a post fire evaluation

- Get in touch today

- We are Great Place to Work Certified!

0 Comments