Brindley Engineering is often called upon to tackle fast-track (emergency) projects on a moment’s notice. One recent event at a Midwest refinery was to take-over a project that was in jeopardy of not meeting its objectives. The unit shutdown was scheduled to begin, and the project was off track for completion to meet the event. Structural and piping design were the major needs for this project and the existing field conditions were challenging but needed to be assessed very quickly.

Interdisciplinary Collaboration is Key

BE Together

Utilizing a combination of 3D design software including Autodesk Revit, Plant 3D, Navisworks, and ReCap, the team collaborated to provide a high-quality package of deliverables, which consisted of an engineered scope of work, detailed structural drawings for the platform, and several overall isometric and spool drawings for the piping fabrication. The use of 3d models that interacted with different software platforms enabled the interdisciplinary coordination, clash detection and precision of the construction drawings in real time. One of the keys to success was a continual and collaborative model updating method where multiple designers could see adjustments in near real-time. Because of this, the team could make informed design changes that did not jeopardize the designs of other disciplines. By the same token, if a design change interfered with other disciplines, the change would be discussed and updated accordingly with updated models redistributed to the team. Consistent interdisciplinary communication was the key to the success of the project.

Our Challenges

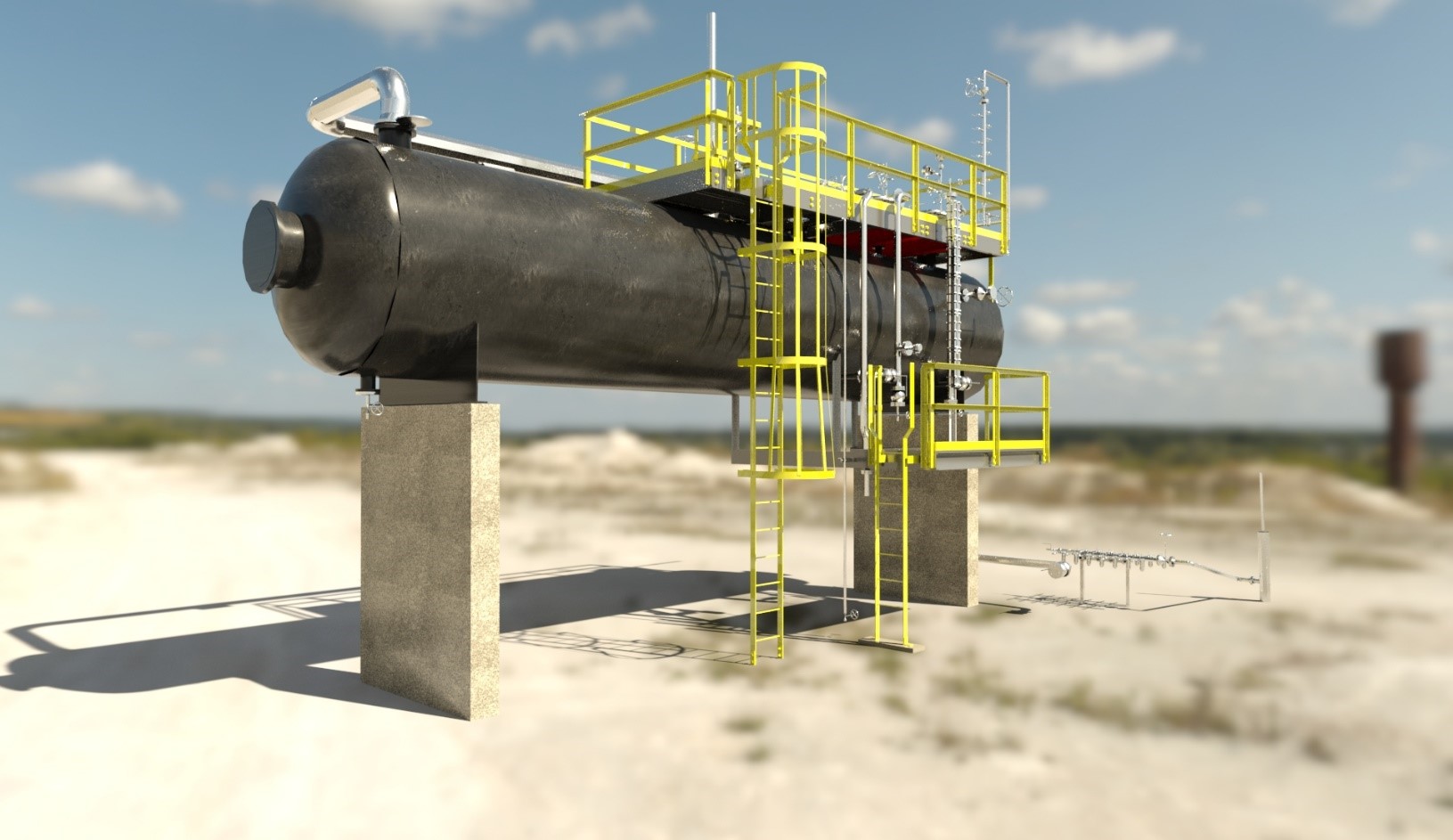

The new Fuel Gas Knockout drum was intended to be an exact replacement of the existing drum, with most of the piping to be re-used and very little replaced. However, after analyzing the survey of the existing drum and comparing it to the original fabrication drawings it quickly became apparent that the existing conditions did not match what was originally designed. Considering the conflicts between the original design documentation and the existing physical conditions – coupled with the fact that a newly fabricated drum was to be installed, meant that any pre-engineering based on the original design would have been a rough draft. A survey and 3D point cloud scan of the new vessel performed in the fab shop was the answer. Upon review of the new data, it was realized that none of the existing piping would be able to be re-used. Working as a team, the surveyors, structural, and piping departments were able to provide highly accurate designs for all new piping and access platform.

BE the Result

Reliable infrastructure that is critical to on-stream efficiency of a process unit is a key to facility profitability. Brindley focuses on the evaluation and repair of existing infrastructure and has a unique combination of knowledge and experience with material selection, constructability, and turnaround execution.

0 Comments