Structural fireproofing reliability is an important safety feature in any organization. There is a myriad of fire protection materials, application companies, and methods out there, and each one spans a wide budget spectrum. Many leaders don’t know where to start. Here is a guide to 5 essential questions you should be considering when researching your options and formulating your passive fire protection plans.

Question 1: What is the danger to people and equipment from falling fireproofing?

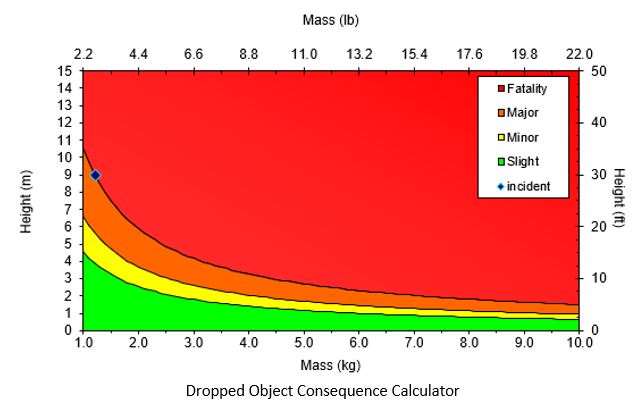

Industrial facilities go to great lengths to mitigate the risk of falling objects, such as “nesting” an elevated work site, using barricades or safety tape, and a host of other measures to ensure the safety of those below. But many of these same facilities do not have an adequate structural and fireproofing evaluation and maintenance program, the lack of which greatly increases the odds of a falling-object incident. To put it in perspective, a piece of concrete the size of an apple falling approximately 30 feet could result in a fatality if it hits an individual, even if wearing standard PPE1. Not only is there a risk to people, but falling concrete can also damage equipment, such as a horizontally mounted pressure gauge, which could break off if struck by falling concrete and result in a loss of primary containment. Even mid-size facilities can have miles of concrete fireproofing and reinforced concrete structures, so the risk is widespread.

In addition to the safety of individuals working within and near these units, there are economic dangers as well. Falling fireproofing is a sign of poor craftsmanship or general deterioration. Either way, if fireproofing is in poor enough condition to be falling off the structure, then typically the underlying structure is in an advancing state of deterioration. Brindley Engineering has evaluated tens of thousands of individual structures within industrial facilities and have found columns that are free-floating and no longer connected to their foundations, beams without flanges or webs, equipment anchors so corroded then shatter on impact, and a host of other problems. When deterioration advances unchecked, there are dangers of collapse and significant cost ramifications to repair.

Talk to a Brindley Engineer Team member today ntriandafilou@brindleyengineering.com!

Note 1: Average apple diameter of 2.7 inches per Wikipedia. Concrete density of 490 pcf. Impact effect per Dropped Object Consequence Calculator (2018) (see www.dropsonline.org)

Talk to a Brindley Engineer Team member today!

- Click here to read Part 2 of 5 Essential Fireproofing Questions

- Click here to read Part 3 of 5 Essential Fireproofing Questions

- Click here to read Part 4 of 5 Essential Fireproofing Questions

- Click here to read Part 5 of 5 Essential Fireproofing Questions

I am a subcontractor that is being asked to fireproof open web angle joist in a school gymnasium. The product is high density spray applied. The roof of this gymnasium is an outdoor sports court. I refused to apply the high density product and suggested an intumescent coating. My fear was falling fireproofing from movement, being hit and also in the long-term denigration. The architect/owner/GC was not happy with me. Ultimately it was sprayed with Intumescent. Now they are asking me for letters to back up my claim this was an unsafe application. So, my comment is, fireproofing fall off is not only due to time and substandard installation as suggested above.

We appreciate you sharing your experience and insight with us, Sam!