Let's Talk Lifting and Rigging with Erick Tobar: Structural Engineer at Brindley Engineering Chicago

Q: Please tell us about your role at BE. What is your day-to-day like?

A: I [Erick Tobar] am involved in a lot of interesting lifting and rigging projects at Brindley Engineering. The jobs I work on typically involve any type of heavy equipment, usually over 20,000 lbs, in which we have to transfer the equipment from one point to another using a crane/s.

Q: Are there any projects that stand out as more complex than others that you have worked on recently?

A: Yep! For one client, we worked on very complicated lifts, for example a valve weighing over 100,000 lbs that was located within a concrete structure, and we were responsible for getting the equipment out of the structure and transferring on to the crane. We also did lift plans in very congested areas in which we were able to use 3d scanning, 3d modeling and simulate the lift prior to execution.

Q: Tell us more about using 3d scanning, 3d modeling and simulations in your work.

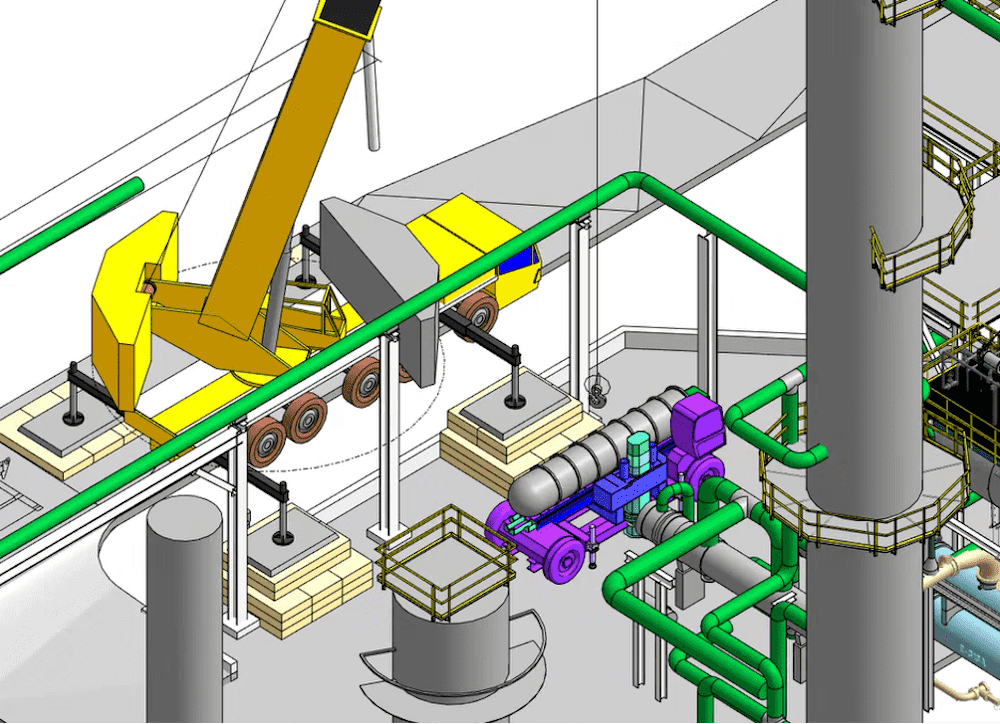

A: 3D scanning and modeling helps us bring the project to real life. We are able to identify any potential obstructions prior to execution. We can model the equipment, rigging and crane as one unit and visualize every stage of the project.

Q: Can we see some of the equipment you use?

A: Here is a glance at a lift plan in a very congested area to replace an exchanger bundle in which 3d scanning and modeling was used to verify all clearances.

A: And here is another one of a valve weighing over 100,000 lbs over a large crane radius with tight clearances.

Q: Does BE have safety standards when it comes to lifting and rigging?

A: At Brindley Engineering, safety is our top priority. It is critical to the well-being of our employees, clients, and the environment. In the process industries, where intricate systems and high-risk operations are the norm, even the smallest oversight can lead to devastating consequences, such as equipment failure, injury, or environmental harm. By embedding safety into every aspect of our designs, we ensure that our systems not only meet performance and efficiency standards but also protect human life and preserve the environment. Our unwavering commitment to safety supports operational continuity, ensures legal compliance, and fosters trust with clients, enabling us to deliver reliable, sustainable, and responsible solutions.

- Get in touch today!

- Learn more about the work we do, and our team, on our YouTube channel.