The Power of 3D Printing for Structural and Mechanical Engineering: 5 Reasons Every Engineering Company Should Have This Design Tool!

At Brindley Engineering, we exist to “BE Creatively Bold” – for our people and our clients. We are a diverse culture of creative engineers, thinkers, athletes, parents, designers, builders, and academics who share the same values and support one another no matter what is going on in front of us or in the world around us. We are always looking for new applications and technologies to design, build, and implement creative, forward-thinking solutions to prevent problems that could threaten keeping projects on track. And we love to build – that’s why we’re engineers and technicians. For an engineering company a 3D printer provides valuable applications that enhance design, testing, and operational efficiency.

Top 5 reasons to have a 3D printer for Structural Engineering Applications:

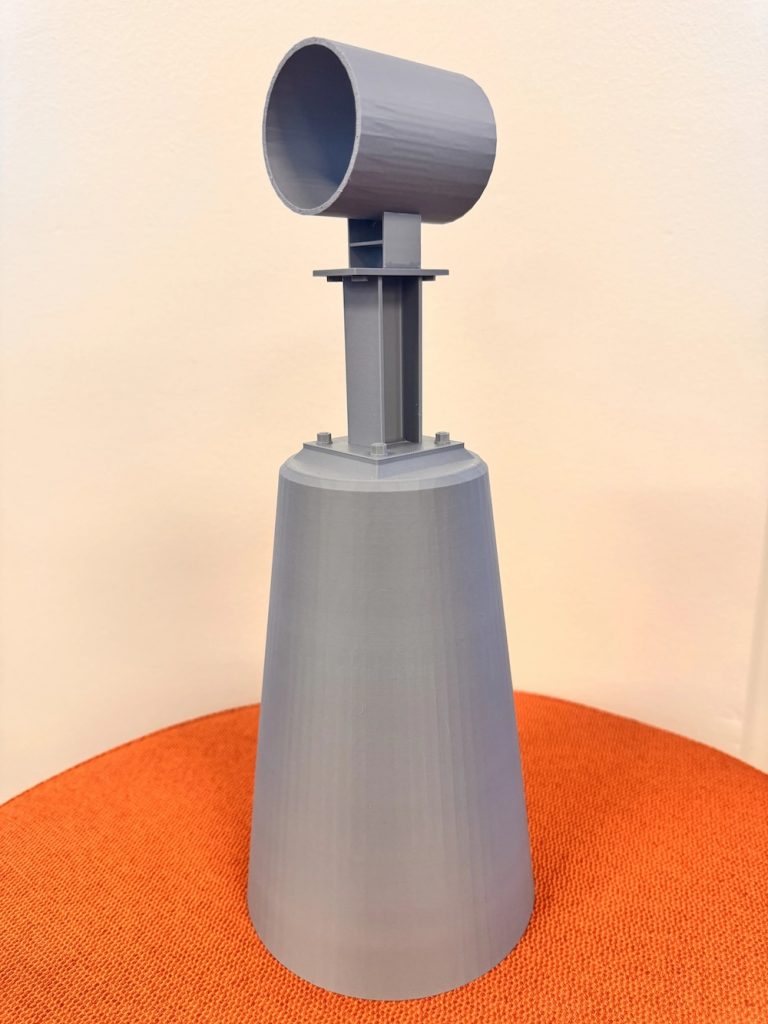

- Prototyping Offshore and Onshore Structures – Engineers can create scale models of platforms, subsea structures, and support frames to visualize load distribution and structural integrity before full-scale fabrication.

- Custom Connectors and Joints – Testing innovative structural joints and connections through 3D printing allows for faster design iterations and better evaluation of material performance under stress conditions.

- Wind and Load Testing Models – Physical models of large structures, such as drilling rigs and FPSOs (Floating Production Storage and Offloading units), can be used in wind tunnel testing and finite element validation.

- Scaffolding and Temporary Support Prototypes – 3D-printed prototypes help engineers optimize temporary structural supports and access systems for on-site maintenance work.

- Integration with BIM (Building Information Modeling) – 3D-printed models help in reviewing complex structural arrangements, ensuring compatibility between steel frameworks, pipelines, and mechanical systems.

Top 5 reasons to have a 3D printer for Mechanical Engineering Applications:

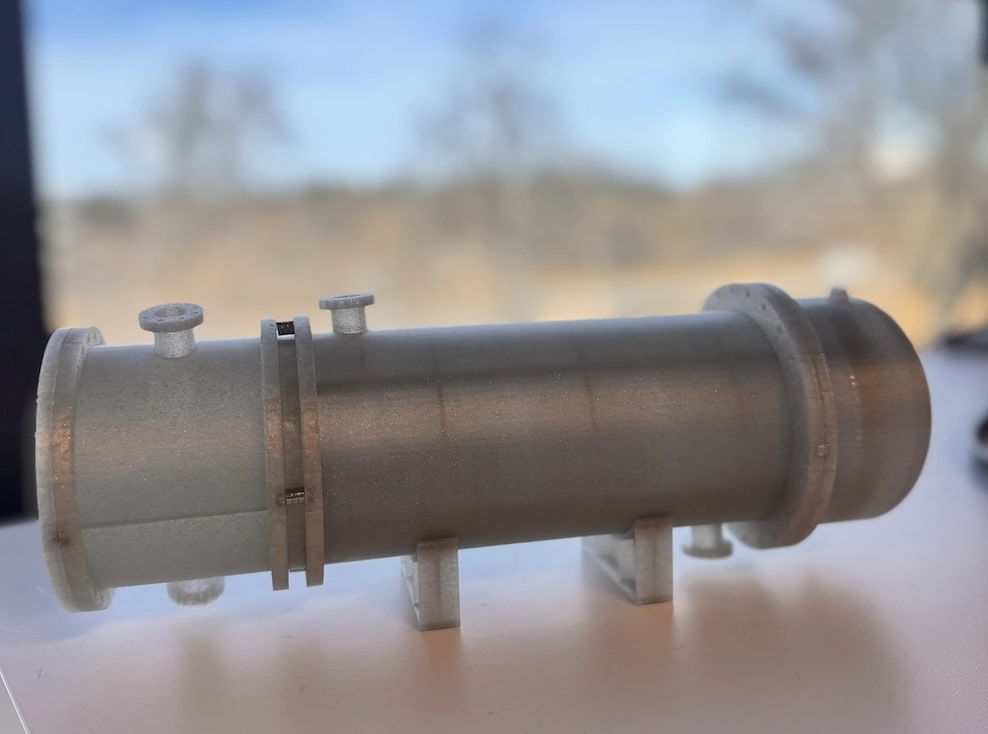

- Component Design and Fit Testing – 3D printing allows engineers to create scaled-down or full-size models of pumps, valves, turbines, and pressure vessels to check compatibility before manufacturing.

- Complex Manifold and Piping Systems – Printing intricate flow channels and pipe networks helps in optimizing designs, reducing pressure drops, and preventing turbulence in critical fluid-handling systems.

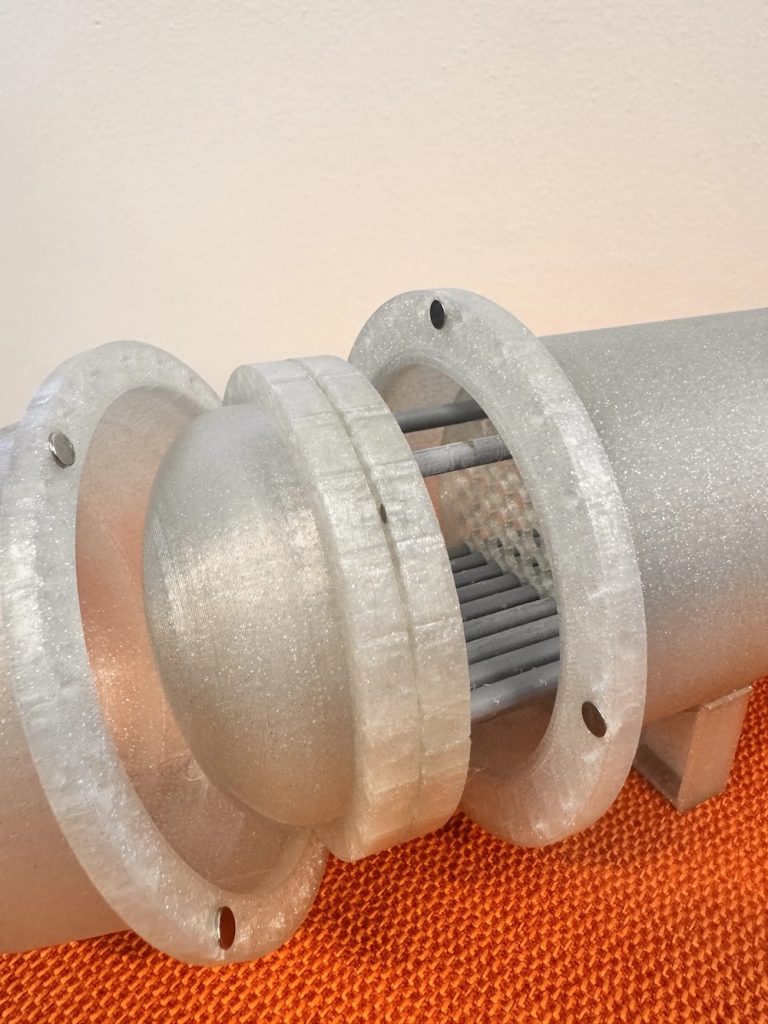

- Heat Exchanger and Cooling System Prototypes – 3D-printed heat exchanger models assist in testing innovative designs with optimized surface areas for better thermal performance.

- Rapid Tooling for Machining and Maintenance – Engineers can create custom fixtures, brackets, and templates for machining or maintenance work, reducing downtime and production delays.

- Material and Wear Testing – Small-scale 3D-printed test models help in evaluating mechanical properties and stress points in components before committing to final metal fabrication.

Effective design comes from a deep understanding of how things are built, and our expertise ensures every project is both practical and constructable.

Learn More About Our Obsession with Building and Creating!